Guide to rubber extrusions

Hebei Shida Seal Group has grown to be a leading OEM supplier of extruded rubber products, extruded rubber profiles, closed cell extrusions, solid rubber extrusions, sponge rubber extrusions, rubber seals, washers, door gaskets, window glazing gaskets, flame retardant and temperature resistant rubber extrusions. Materials include EPDM, NBR, dense or sponge rubber, and silicone. Secondary operations include splicing into rings, vulcanized corners, frames, cut to size and continuous lengths. Serves the automotive, aerospace, marine, medical, agricultural and building industries.

Hebei Shida Seal Group has grown to be a leading OEM supplier of extruded rubber products, extruded rubber profiles, closed cell extrusions, solid rubber extrusions, sponge rubber extrusions, rubber seals, washers, door gaskets, window glazing gaskets, flame retardant and temperature resistant rubber extrusions. Materials include EPDM, NBR, dense or sponge rubber, and silicone. Secondary operations include splicing into rings, vulcanized corners, frames, cut to size and continuous lengths. Serves the automotive, aerospace, marine, medical, agricultural and building industries.

This rubber extrusions guide has been designed to help engineers with the initial prototype stage and for those who are looking to buy a new product.

What is a rubber extrusion?

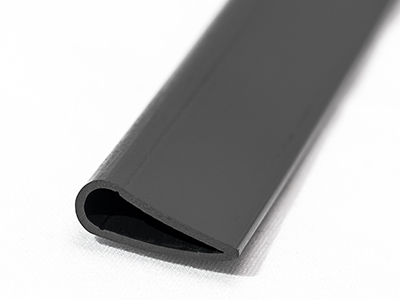

Rubber extrusions are continuous profiles, used often in sealing applications, such as doors and windows, weather strip, draught excluders. Or more robust applications, such as D-fenders on ships. Extrusions can range from simple geometric shapes, through to complex seal designs using dual materials. The name relates directly to the manufacturing method, and although this, of course, is not the only way of producing a length of rubber, it is the most effective way of creating consistent, continuous lengths of profiled rubber.

How is an extrusion made?

Rubber extrusions are produced using a die; a metal disk with a machined opening in the shape of the profile required. Behind the die sits the extruder, a rotating screw inside a heated cylinder, into which the raw compound, pigments, curing agents and other specialist ingredients are fed. The screw forces the uncured material out through the die cavity under considerable shear and heat. On exiting the die, the material must be cured; this can happen using a variety of processes including ovens, microwaves, and water, and is often part of a continuous process. The final production step will be finishing – adding coatings, cutting to lengths, and so forth.

Bespoke rubber extrusions

Bespoke rubber extrusions

There are a range of dies already manufactured and available for use; the more popular extrusion profiles are kept in stock and you can order these as required, by the metre. If an extrusion is required to a profile not currently in existence, a die can be manufactured specific to your requirements; this will incur a tooling cost and a minimum order quantity but will result in a bespoke product to cater for your precise needs.

The benefits of rubber extrusions compared to other sealant materials

Extruding a profile in this way will mean a consistent, repeatable product, which can be cut to length to suit the application in question. Rubber mouldings, by comparison, are restricted by the size of the press in which the product is manufactured, and therefore the maximum straight length achievable would usually be around 1m. Rubber sheet can be stripped to produce square or rectangular profiles but it is restricted both in terms of tolerances, and size/shape – an extruded product may hold tighter tolerances and much smaller shapes/thinner sections, and more intricate geometries.

Due to the method of manufacture, for some applications extruding will be a more cost-effective solution, particularly if large quantities are required; the tooling is generally less expensive than a moulding tool, whilst maintaining greater accuracy than a stripped product. Whilst hardness may be a restricting factor in extruding (very soft grades can be difficult to extrude), there are a wider range of materials available for use, and if aesthetic finish is a concern, colour matching in materials such as silicone can be undertaken.