Custom Electrical Enclosure Seals, Gaskets And Weatherstrips Manufacturers and Suppliers from China

Gaskets, seals and weather stripping should not be overlooked when designing a new electrical enclosure. The product selection, including the material, the density of the material, and the amount of compression required to create a secure fit, is a critical consideration to prevent air, dirt, and moisture from damaging the equipment and to create a more desirable user experience.

Hebei Shida Seal Group is a leader supplying rubber seals, gaskets and weather stripping that secures and protects enclosures for work and service vehicles, heavy equipment, HVAC, telecommunications and electrical cabinets, power generation and more. We understand how to identify the best gasket, seal or weather strip to enhance ease of access, security, and manufacturing efficiency. We are committed to creating higher quality rubber products that deliver more value to their customers.

Type of gasket, seal and weather stripping:

Type of gasket, seal and weather stripping:

- PVC Edge Trim: Flexible PVC trim, includes internal metal clips and gripping tongues for strong grip

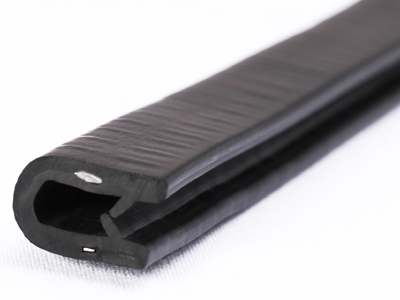

- Rubber Edge Trim: Available in EPDM or Neoprene. Butyl sealant, available for improved grip and excellent sealing

- Trim Seal: Flexible PVC trim with bulb attached Secure predictable seal for gaps

- Sealing Profile EPDM: soft rubber carrier with a bulb attached Secure predictable seal for gaps and sealing apps

- Sponge Rubber or Rubber Seal: Custom formulate sponge rubber compound

- Glazing Profile or Locking Gasket: EPDM dense rubber extrusion designed to create a locking seal

Difference between a gasket, seal and weather stripping:

- Gasket – A gasket fills the space between two or more static surfaces. Gaskets help prevent leakage from outside sources while compressed.

- Seals – Seals are designed for multiple purposes, from keeping two materials joined, or preventing dangerous leaks. The seals are used to control intrusion of air, water, and dirt. In general, seals come in three different types: o-ring, rubber seal, and bearings.

- Weather stripping – Weather stripping is a seal designed specifically for exterior use. It keeps rainwater or melting snow, water, dust, dirt, or particles out of an interior environment, such as the cab of a truck, a power generation unit, or any enclosure.

Types of polymer materials to make gaskets, seals, and weather stripping :

Types of polymer materials to make gaskets, seals, and weather stripping :

Gaskets, seals, and weather stripping come in a range of polymers that allow a manufacturer to meet a specific need while addressing hurdles such as extreme heat or consistent exposure to sunlight.

- EPDM (Ethylene-Propyline-Diene-Monomer) – Excellent for outdoor use – strong resistance to ozone, weathering and aging, as well as water and stream resistance. Not recommended for resistance to oil, gasoline or hydrocarbon solvents.

- Neoprene (polychloroprene) – Moderate resistance to oils and gasoline. Good flame resistance. Weathers well and has good resistance to abrasion, flex cracking, alkalis, and acids. Good, all-purpose elastomer with a good balance of properties and few limitations.

- Nitrile (acrylonitrile-butadiene) – Very good oil and abrasion resistance to alkalis and acids. Poor resistance to oxygenated solvents. Superior to neoprene in oil and solvent resistance. Not recommended for outdoor applications; poor resistance to weathering.

- TPE (thermoplastic elastomers) – Features the properties and performance of rubbers but processed like thermoplastics. Good flame resistance. Resistant to aliphatic and aromatic hydrocarbon solvents, including oil and gasoline.

- PVC – Excellent impact strength. Good resilience, tensile strength, abrasion resistance and maintains flexibility at lower temperatures. Not recommended for oil, gasoline or hydrocarbon solvents.

Aplications of gasket, seal and weather stripping:

Aplications of gasket, seal and weather stripping:

- HVAC

- Construction

- Agriculture

- Enclosures and Storage Units

- Electrical Enclosures

- Telecommunications

- Power Generation

- Kiosks and Carts

- Transportation (trucks, buses, RVs, etc.)

- Heavy Equipment

- Powersports (snowmobiles, boats, ATVs, motorcycles, etc.)

- Work and service vehicles

Why Choosing Hebei Shida Seal Group?

We always manufacture our Electrical Enclosure Seals, Gaskets And Weatherstrips from the highest quality compounds available. This ensures that our Electrical Enclosure Seals, Gaskets And Weatherstrips are not only suitable for use, but also made to last. Despite offering high strength and tear resistance, our seals are also highly flexible. This enables our rubber seals to fit around a wide variety of curves.

Our facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision extruded Electrical Enclosure Seals, Gaskets And Weatherstrips in quantities from short run to full production runs. We have 5 extrusion lines, continuous cure microwave, precision cutting, and splicing machines, and also provide value-added finishing services. In addition, we offer in-house tool, and mold design and manufacturing to ensure that your Electrical Enclosure Seals, Gaskets And Weatherstrips are manufactured to the most exacting requirements.

Hebei Shida Seal Group is uniquely qualified to manufacture Electrical Enclosure Seals, Gaskets And Weatherstrips for your application. Our quality management system is IATF 16949:2016 accredited. We can provide PPAP Level 3 documents for OEM clients.

If you want to contact us about any issue please call (+86)319 8032626 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.