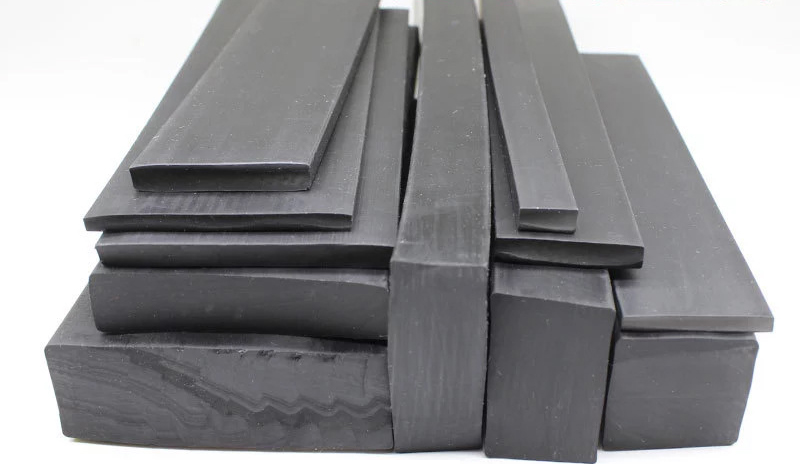

What is EPDM Rubber?

EPDM (ethylene propylene diene monomer) is a synthetic rubber made up of ethylene, propylene, and diene monomers. Its molecular structure has a single bond, chemically saturated backbone, which makes it extremely resistant to outdoor conditions. This is because ozone and UV rays aren’t able to break up its molecular structure in the same way as rubbers with double bonds.

EPDM Properties

EPDM Properties

EPDM’s biggest advantages lie in how weatherproof it is outdoors. It can resist abrasion, UV rays, ozone, aging, and weather, and it’s the most waterproof rubber available. EPDM is also steam resistant, functioning in up to 392 degrees F (200 C) without air, and chemical resistant, including to polar fluids. With similar properties to silicone rubber below 250 degrees F, EPDM is resilient, has low electrical conductivity, and adheres easily to metals. It’s also very flexible, with 600% elongation and a tensile range of 500-2500 psi, while functioning well in temperatures from -50 degrees F (-45 C) to 350 degrees F (177 C). On top of that, EPDM insulates and reduces noise, part of the reason it’s so commonly used in the automotive industry.

How long does EPDM last? It depends on the application it’s used in as well as the conditions under which it’s working. When constantly working at the extremes of its working temperature, EPDM’s lifespan will shrink dramatically. However, if properly taken care of, EPDM products can last for decades. Roofing made from EPDM can last 30-50 years, and liners can last for 20.

EPDM’s most major drawback is its vulnerability to solvents, hydrocarbon oils, and some lubricants, which can cause damage. Additionally, unlike silicone, it’s not flame resistant, and it’s also not recommended for food application. Finally, while EPDM has fair tear resistance, other rubbers such as SBR are better.

What is EPDM Rubber Used For?

What is EPDM Rubber Used For?

EPDM is used as a cheaper alternative to silicone rubber for parts that will have a lot of outdoor or moisture exposure, or for electrical insulation. However, it can also be used as roofing or liners. It’s mainly used in four industries:

- Automotive. This is EPDM’s most common application, thanks to its flexibility, resiliency, and weatherability. It can be found in vehicle weather stripping, seals, sealant, wire and cable harnesses, and brake systems. It’s also blended with other materials to make fender extensions, rub strips, and car bumpers.

- Industrial. Industrial applications use EPDM for its electrically insulating and waterproof properties, as well as its resilience and flexibility. EPDM can be found in parts such as water system O-rings, hoses, and gaskets, as well as in electrical insulators and connectors for wire and cable. It also takes the form of accumulator bladders, diaphragms, grommets, and belts.

- Construction. Thanks to its insulating, weatherproof, and waterproof capabilities, roofing is a major application for EPDM. However, it is also used for sealant, expansion joints, garage door seals, pool and tank liners, and waterproof coating for bitumen roofs. It’s even used on RV roofs.

- HVAC. In this industry, EPDM takes the form of grommets, tubing, gaskets, seals, and insulation, thanks to its weatherability and temperature resistance.

Conclusion

We hope this short guide on EPDM rubber, covering its makeup, properties, and applications, has been helpful to you in your sourcing. EPDM rubber is only one of several kinds of rubber used in industry today, however. If you’re more interested in sourcing EPDM rubber products now, we can help with that too.