Rubber molding is dominated both in the US and internationally by some very large, vertically-oriented producers. In the automotive sector, for example, companies such as Tenneco produce vast quantities of rubber parts for automotive OEMs which are used as individual components and as parts in manufactured assemblies. Such suppliers are not likely to be in a position to accept orders for custom molded rubber parts due to the sheer volume of business they receive from their regular customers. Still, molded rubber parts are critical in many commercial products ranging from appliances to medical devices.

Image credit: oYOo/Shutterstock.com

With that in mind, this article steps back a bit from listing the gargantuan companies for whom rubber molding is but a part of their larger operations and instead looks at US companies that do rubber molding as their main, or major, endeavor. For anyone looking to source rubber molded products in the US, it is highly likely that any of the companies listed here would be happy to receive a call.

Top US Rubber Molders

Table 1 below ranks the US molders of custom rubber products listed in descending order by estimated revenue.

Table 1 Top US Molders of Custom Rubber Goods1

| Rank | Supplier | Activity | Location | Year founded | Sales $ |

| 1 | Fairchild Industries | Cust. Manufacturing | Lake Zurich, IL | 1956 | 250 mil + |

| 2 | Flexan | Cust. Manufacturing | Elk Grove Village, IL | 1989 | 250 mil + |

| 3 | Garlock | Cust. Manufacturing | Arcadia, WI | 1945 | 250 mil + |

| 4 | JDS Technologies | Cust. Manufacturing | Oneida, TN | — | 250 mil + |

| 5 | MoldTech | Cust. Manufacturing | Lancaster, NY | — | 250 mil + |

| 6 | Robin Industries | Cust. Manufacturing | Independence, OH | — | 250 mil + |

| 7 | Robinson Rubber | Cust. Manufacturing | Minneapolis, MN | 1945 | 250 mil + |

| 8 | Ames Rubber | Cust. Manufacturing | Hamburg, NJ | 1949 | 25-50 mil |

| 9 | Clark Rubber & Plastic | Cust. Manufacturing | Mentor, OH | 1971 | 10-25 mil |

| 10 | Custom Rubber | Cust. Manufacturing | Cleveland, OH | 1956 | 10-25 mil |

| 11 | Da/Pro Rubber | Cust. Manufacturing | Broken Arrow, OK | 1960 | 10-25 mil |

| 12 | Goodyear Rubber | Cust. Manufacturing | Rancho Cucamonga, CA | 1961 | 10-25 mil |

| 13 | Modus Advanced | Cust. Manufacturing | Livermore, CA | 1976 | 10-25 mil |

| 14 | Rubber Associates | Cust. Manufacturing | Barberton, OH | 1940 | 10-25 mil |

| 15 | Stern Companies | Cust. Manufacturing | Baxter, MN | 1995 | 10-25 mil |

| 16 | Universal Polymer & Rubber | Cust. Manufacturing | Middlefield, OH | — | 10-25 mil |

| 17 | VIP Rubber and Plastic | Cust. Manufacturing | La Habra, CA | 1961 | 10-25 mil |

| 18 | Cooper Products | Cust. Manufacturing | Laconia, NH | 1973 | 5-10 mil |

| 19 | Industrial Molded Rubber Products | Cust. Manufacturing | Big Lake, MN | 1968 | 5-10 mil |

| 20 | Performance Polymer Technologies | Cust. Manufacturing | Roseville, CA | 1955 | 5-10 mil |

| 21 | RD Rubber Technology | Cust. Manufacturing | Santa Fe Springs, CA | 1986 | 5-10 mil |

| 22 | Santa Fe Rubber | Cust. Manufacturing | Whittier, CA | 1966 | 5-10 mil |

Company Summaries

Fairchild Industries manufactures a comprehensive line of industrial and automotive door seals, weatherstripping, and the like. It also offers custom rubber molding services to automotive, agricultural, and industrial OEMs, as well as Tier 1 and aftermarket suppliers. The company provides a full plate of engineering and design services to accompany its custom moldings.

Flexan molds silicone rubber and plastic medical components with facilities in both the US and China. Molding is performed in cleanrooms to conform to the requirements of medical device manufacturing. The company began in 1946 by producing a rubber mold over a metal plate which Sears used in the development of a flexible sander.

Garlock, widely known for its gaskets, packings, and seals, also maintains a custom rubber molding operation with a gang of presses available to produce injection, compression, and transfer molded parts. The company works with the full range of available elastomeric materials and offers compounding and custom mixing, as well.

JDS Technologies, based in Oneida, TN, molds custom rubber products for the oil and gas, aerospace, automotive, appliance, and medical industries. Products include gaskets, seals and O-rings, hoses, duckbill valves, pipette bulbs, etc. A second facility in Louisiana specifically manufactures oilfield products.

MoldTech offers its customers in the aerospace, automotive, consumer goods, medical, and similar industries a full range of services from engineering to compounding in the production of molded rubber goods. The company’s manufacturing capabilities include compression, transfer, and injection molding at its facility in Lancaster, NY.

Robin Industries caters to the medical device and automotive industries, providing compression, transfer, and injection molding of custom elastomer products. The company maintains operations in the US, China, and Mexico, and provides a host of value-added services from design engineering to material formulation.

Robinson Rubber manufactures custom molded rubber items for a variety of industries with products ranging from spark plug boots to pump impellers. The company sources manufacturing to factories through its global initiatives program, while maintaining engineering expertise in house. The company publishes several documents on rubber molding.

Ames Rubber, of Hamburg, NJ, provides rubber molding and coating services to a variety of customers in industries from aerospace to medical device manufacturing. The company specializes in developing industrial elastomers for a variety of applications. Its AMESShield, for instance, is a spray-on elastomeric coating designed to protect aero-engine components from corrosion.

Clark Rubber & Plastic provides natural and synthetic rubber molding services to industries ranging from solar energy to heavy-duty trucking. The company also provides a range of plastics forming services, which it conducts in a facility separate from the rubber molding operations.

Custom Rubber molds rubber into a variety of parts such as pads, bellows, grommets, hand grips, etc. for industrial machinery, material handling, and similar applications. The company also sells a variety of stock molded products such as pads and dock bumpers.

Da/Pro Rubber produces OEM rubber components using compression, transfer, injection, and micro-molding techniques. Customers range from aerospace to medical device manufacturers. The company operates five manufacturing facilities, with three in the US and two in China.

Goodyear Rubber, based in southern California, produces custom molded parts from natural and various synthetic rubbers. The company provides services to the aerospace and defense, mining, automotive, food processing, and similar industries. All manufacturing is done in the US.

Modus Advanced is a manufacturer of EMI shielding and die-cut gaskets that also produces custom silicone and natural molded rubber products in the US and in China. The company’s website offers detailed advice not only on the engineering aspects of custom molded parts but also considers the sourcing of products domestically versus overseas.

Rubber Associates specializes in custom rubber molding using compression, transfer, and injection molding techniques. The company works with EPDM, natural, nitrile, and other rubber materials, operating out of a 75,000 sq. ft. facility in Barberton, OH.

Stern Companies specializes in rubber and plastic molding through overseas manufacturing. In addition to rubber injection, transfer, and compression molding, the company provides plastics rotomolding, thermoforming, and similar services to OEM clients, with headquarters in Baxter, MN.

Universal Polymer & Rubber manufactures molded natural and synthetic rubber parts at a 150,000 sq. ft. facility in Middlefield, OH. The company has the expertise to guide customers in the best molding method for their rubber parts and will complete any secondary manufacturing operations such as deflashing on site. Products include EPDM rubber tarp straps and drainage pipe gaskets.

VIP Rubber and Plastic conducts all of its rubber compression, transfer, and injection molding operations at its La Habra, CA facility. The company’s website provides detailed information on the benefits and disadvantages of each molding process, a useful primer for clients wishing to source rubber molded parts.

Cooper Products manufactures custom radial shaft seals for use with bearings. The company manufactures all of its products in its Laconia, NH facility and provides custom molding of rubber products in low- and medium-volume runs in addition to its seal manufacturing operation.

Industrial Molded Rubber Products provides custom rubber injection, transfer, and compression molding services to a variety of industries from packaging machinery to oilfield products. The company also provides rubber-to-metal bonding and roller re-covering services.

Performance Polymer Technologies produces custom molded silicone and organic rubber parts for the aerospace and defense, medical, semiconductor, and instrumentation sectors. The company provides a suite of services as well, including materials selection, tooling design, and manufacturing process development.

RD Rubber Technology specializes is liquid silicone rubber injection molding, a two-component process that produces fast cure rates. The company can produce custom rubber molded goods in a cleanroom environment, as befitting the manufacture of non-implantable medical devices such as blood pumps and I.V. systems.

Santa Fe Rubber produces custom rubber parts using compression, transfer, and injection molding processes. The company serves the rubber molding needs of military and defense, automotive, oil and gas, instrumentation, and similar industries.

Summary

This article summarized the top US-based rubber molders capable of producing custom products. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

FORT WAYNE, Ind.—Linda Muroski, president of Trelleborg Sealing Solutions Marketing Americas and the Global Healthcare and Medical segment, has been named one of Industry Era’s 10 Most Inspiring Women Leaders of 2021.

FORT WAYNE, Ind.—Linda Muroski, president of Trelleborg Sealing Solutions Marketing Americas and the Global Healthcare and Medical segment, has been named one of Industry Era’s 10 Most Inspiring Women Leaders of 2021.

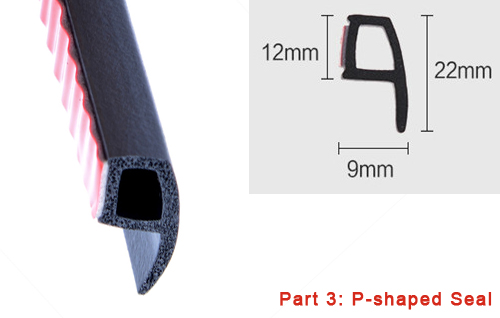

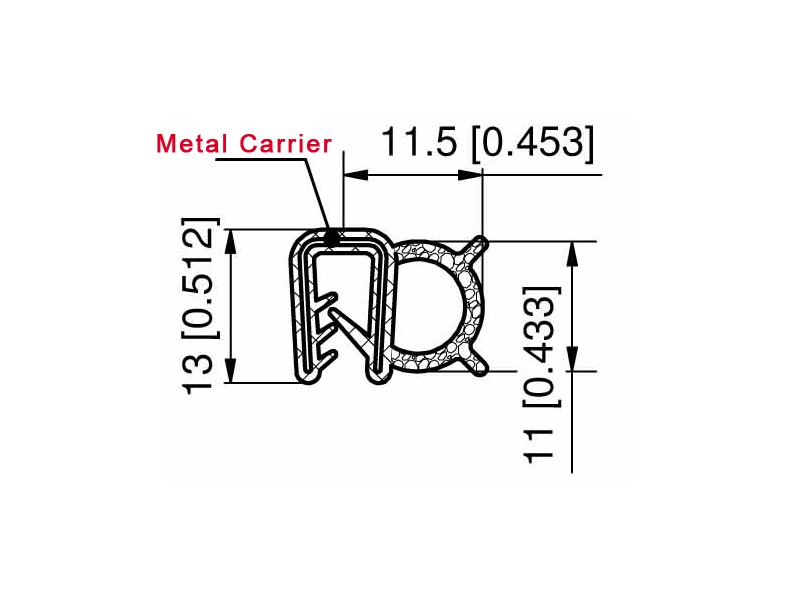

Gaskets made of fire protection compound fixed by securing in a U-section

Gaskets made of fire protection compound fixed by securing in a U-section