Biomimetics is on everyone’s lips and it is now difficult to imagine a future where it does not play a key role in the development of our society. The development of new materials is not unconcerned with this new discipline, though we must be aware of what we can obtain (and what we cannot) from imitating nature.

Materials for the Carbohydrate Economy

One of the most significant future transformations in the material sphere will be the development of a carbohydrate economy. This will be a global economy based primarily on renewable material feedstocks—as opposed to our current economy, which is founded largely on fossil fuels.

Mystic Vehicle of Contemporary Technology

If you carefully observe designed objects around you, perhaps you may find the unspoken process of their birth. Their ingredients and parts should come from somewhere in this globe, and mixed and combined together in a factory of somewhere, through hands and ideas of somebodies.

Iran, France Sign MoU to Produce Car Rubber Parts in Iran

Iran and France signed a memorandum of understanding on Tuesday to produce automotive rubber parts in Iran in an agreement that is set to turn domestic producers into parts suppliers for French carmakers.

The agreement was signed by Mehdi Nekoumanesh, head of Iran Polymer and Petrochemical Institute (IPPI), and the president of Union des Syndicats des PME du Caoutchouc et de la Plasturgie (UCAPLAST), Denis Vaillant, Shana News reported.

UCAPLAST is an independent employers’ organization which represents all small and medium-size French enterprises in the rubber and plastics industry.

The MoU calls for sharing expertise of UCAPLAST member companies with Iranian manufacturers.

Affiliated to the Ministry of Science, IPPI oversees activities of 20 knowledge-based companies which produce rubber parts for automobiles.

The businesses are expected to sign an auto parts and supplies contract with the French automaker Citroen. The French company already has a joint production deal with Iran’s second-largest automaker SAIPA.

According to the deal, Citroen is required to export 30% of vehicles or auto parts manufactured under the JV through its international sales network.

The IPPI-UCAPLAST arrangement will enable local auto parts suppliers to make products that meet Citroen standards.

The MoU was signed on the sidelines of 11th International Exhibition of Plastics, Rubber, Machinery, and Equipment (Iran Plast 2017) held Sept. 24-27 in Tehran.

Easy Exports

For selling vehicles and components in the EU and countries under the United Nations Economic Commission for Europe Regulation 10, companies must have the E-mark certificates for their products.

However, according to the Head of the Bureau Veritas automotive department in Iran, Mehdi Parvini plastic automotive parts used in vehicles’ interior are exempted and do not need the certificates.

Obtaining E-mark certificates is an arduous and time-consuming exercise and seen as a hurdle to automotive exports from Iran. Therefore, it would be easier for Citroen and other French auto companies operating in Iran — namely Renault and Peugeot — to export plastic automotive parts produced in Iran through their international networks instead of exporting vehicles or engine parts.

Outdated technology used by Iran’s supply chain are seen as a hurdle in the way of expanding the local automotive industries and implementing local carmakers joint venture contracts with foreign firms.

Law stipulates that in all new agreements signed with foreign companies at least 40% of the vehicle parts should be manufactured in Iran. However, foreign carmakers are reluctant to comply for more reasons than one.

The IPPI-UCAPLAST deal should contribute to the implementation of the new JVs with foreign firms because plastic parts have an obvious share in the production of vehicles.

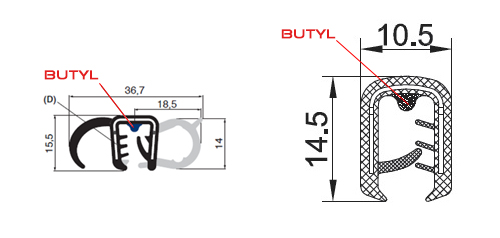

Pre-applied Butyl Sealant

Pre-applied Butyl Sealant

For better insulation properties, we can add / inject Butyl to trims, and seals such as door weatherstrips, trunk seals, trim seals, rubber edge trims, door sealings, edge protectors, edge protection sealing profiles can be provided with pre-applied butyl sealant at an additional cost to provide an improved grip and a positive seal with excellent heat reistance.

Keywords: rubber extrusions with injected butyl, rubber seals with butyl, rubber profiles with injected butyl, edge trims with butyl, butyl sealant, Butyl Injection, rubber edge trim with butyl adhesive

Cooper Standard opens new facility in Canada

SHERBROOKE, Quebec—Cooper Standard Automotive Inc. celebrated the grand opening of a new, 138,000-sq.-ft. site in Sherbrooke dedicated toward its Industrial Specialty Group.

The $10 million project consolidated three existing ISG facilities, bringing 250 employees under one roof. The site will produce extruded EPDM rubber sealing products for the non-automotive industrial, commercial and specialty vehicle markets. The site also will house a new enterprise resource planning system and provide employee skill enhancement programs.

North America President Bill Pumphrey said during a ribbon cutting ceremony on Sept. 21 that the $3.47 billion automotive supplier sees significant opportunities in the non-automotive sectors.

Sherbrooke Innopole worked closely with Cooper Standard during the completion of the project, which took two years.

ISH is a dedicated group within Cooper Standard that serves the power sports, marine, agriculture, construction, commercial vehicle and recreation vehicle markets.

Based in Novi, Mich., Cooper Standard is a leading automotive supplier with four core product focuses—rubber and plastic sealing, fuel and brake lines, fluid transfer hoses, and anti-vibration systems with 30,000 employees in 20 countries.

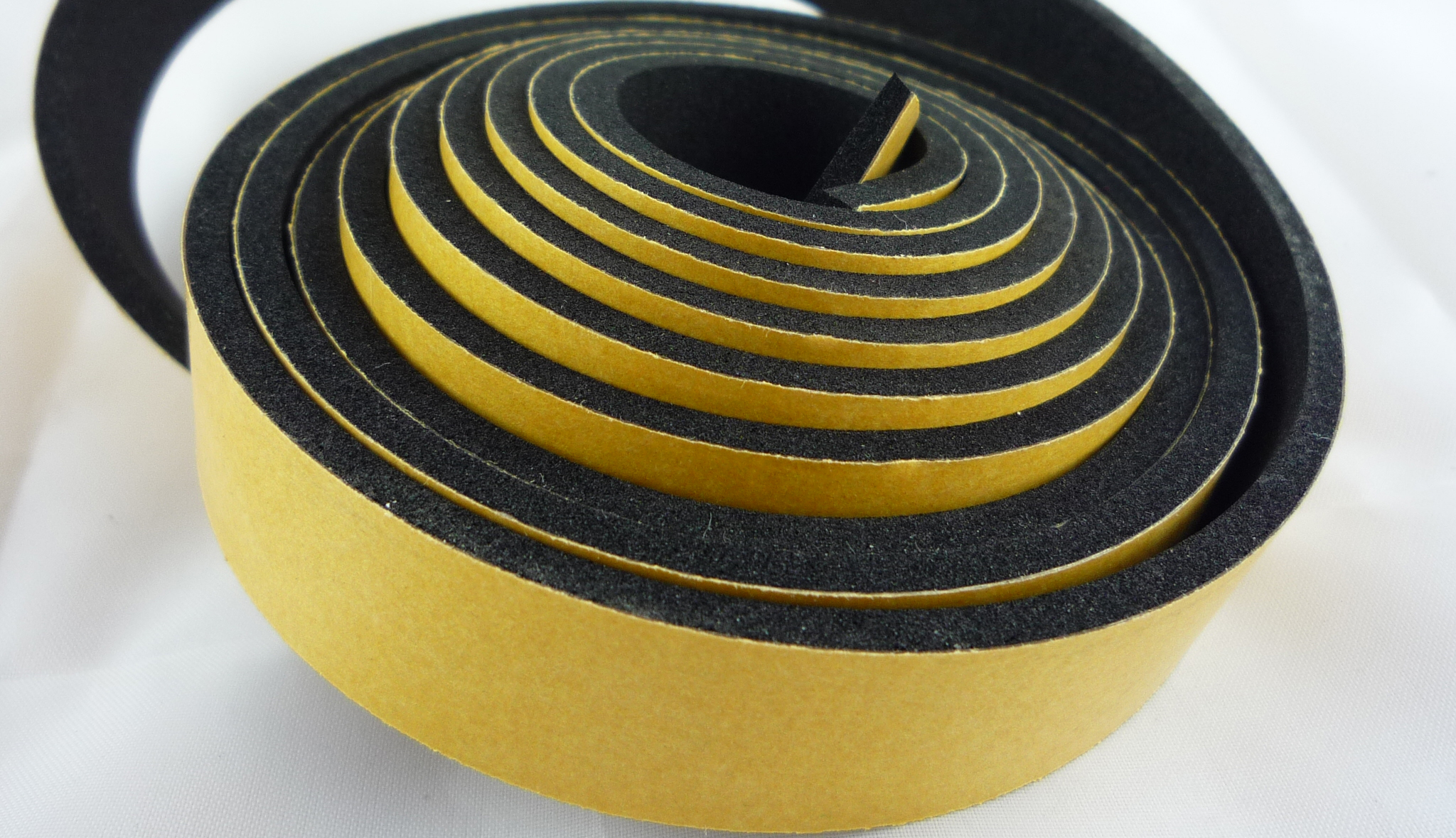

About Closed Cell Sponge Rubber

Closed cell sponge (or foam) is one of the two major categories of sponge material (the other category is open cell sponge). Closed cell sponge is a type of expanded rubber. Closed cell sponge is created when the bubbles produced during the manufacturing process are completely encompassed within the liquid raw material used to make the sponge. When the liquid sets, the gases are entirely encapsulated within each individual bubble, creating a solid yet lightweight structure.

Closed cell sponge is an extremely versatile material from which a variety of products can be fashioned. Because it is particularly good at keeping out moisture and water, closed cell sponge is very effective in applications where a watertight seal is required.

Closed-cell sponge does not have interconnected pores. As a result, closed cell sponge has a higher compressive strength than open cell sponge due to its structure. Closed cell sponge also possesses a higher dimensional stability, low moisture absorption coefficient, and higher strength compared to open cell sponge.

Closed Cell Sponge Applications and Products

At Hebei Shida Seal Group we make a wide range of products from closed cell sponge which service a diverse range of applications and uses. These include parts for automotive vehicle applications and general industrial use. Examples of products and parts that we have produced from closed cell sponge include: isolators, dual extrusions and weather stripping.

Closed cell sponge is an appropriate material to consider for any of the following types of applications:

- Thermal insulation

- Seals and gaskets which protect against the intrusion of moisture, UV light, or dirt

- Joint fillers and edge extrusions

- Packaging

Types of closed cell sponge material which we stock includes the following:

- Closed cell neoprene sponge rubber

- Closed cell EPDM sponge rubber

- Closed cell PVC/NBR sponge rubber

- Closed cell urethane sponge rubber

- Closed cell silicone sponge rubber

For further information on any of our closed cell sponge rubber products we can manufacture, contact our sales department at [email protected].

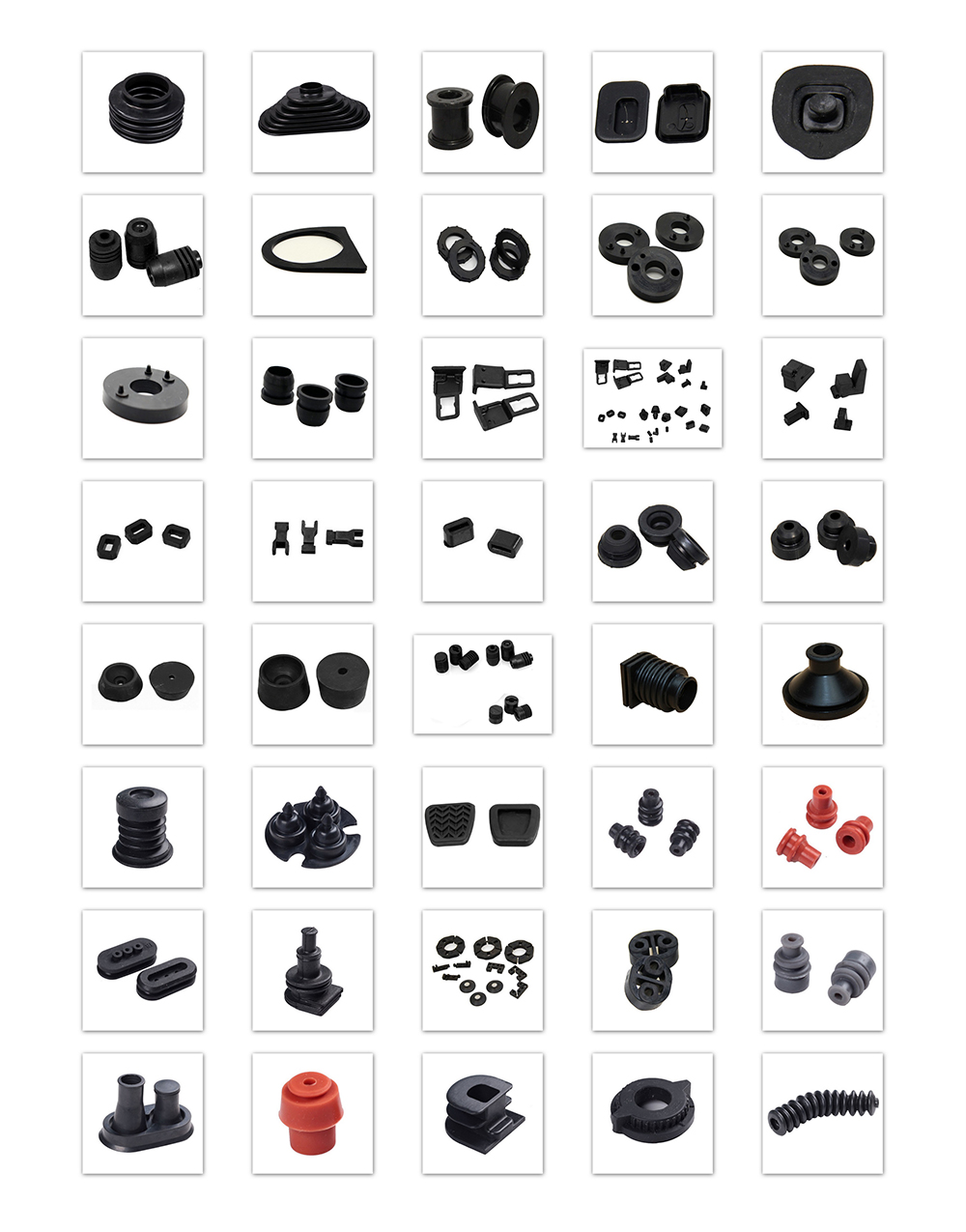

Rubber Molded Parts

Rubber bellow for hatchback

Rubber cylinder

micro rubber gaiter

Turn-up Bladder for tyre production

Breathing mask

Silicon grommet for auxillary heating

Knob sleeves for carpentry machines

Seals for gear housing

Seals for electronic components

Oil pressure line for motor saws

seals for labelling systems

Grommet

End wall seal for air conditioning

Control device sealing

Seals for printing machines

Slanted grommet for wiring harnesses

Protective housing for measurement device

Closing caps

sealing control value

sensor sealing

Grommet for engine test bench

Rubber bellow for mirror setting

Flat gasket

Grommet for the wiring harnesses

Spray nozzle for sanitary technology

Membrane for medical technology

frame sealing

Hole disc for cleaning machines

Grommet for the electronics industry

block sealing

control sealing

Rubber bellow for blinker lever

Grommet for the wiring harnesses

Covers for dental medicine

Rubber bellow for air conditioning

grommet with diaphragm

Falling protection for crane control

Protective shell for measurement device

Fuel hose for motor saws

Housing seal for plug

hearing aid gasket

Truck-dust discharging value

gasket for auxiliary heating

Damper ring for riddle screens

Silicon protective shell for foodstuff industry

Dust discharging value

Protecting housing for control device

Rubber bellow for car electronics

oval piston seal

Distance piece for dental medicine

Oil suction line for motor saws

Double diaphragm sealing

Rubber buffer for bodywork

Instrument plating for dental medicine

Rubber bellow for electronic technology

Sealed housing for motor vehicle lighting

Protective shell for hand lamp

Rubber bellow for filter technology

Protective housing for electronic measurement device

Auxiliary heating gasket

Suction hose for motor saws

Air chamber as Lordosis support

conpensation sealing

Silicon moulded parts, lids, breathing masks, seals, sealing rings, sealing washers, rubber bellows, moulded hoses, rubber profiles, rubber buffers, catheters, fuel hoses, paste rolls, sleeves, membranes, protective housing, protective caps, silicon membranes, silicon suction cups, special seals, mirror caps, plugs, grommets and closing caps.

Ethylene Acrylate Rubber (AEM, Vamac® )

Ethylene/Acrylic elastomer (AEM, Vamac®)

Ethylene/ acrylic elastomer is a copolymer of ethylene and methyl acrylate plus a small amount of a curesite monomer containing carboxylic acid groups. AEM is a tough, low-compression-set rubber with excellent resistance to high temperatures, hot mineral oil, fluids and weathering. The low temperature flexibility and mechanic properties are better than ACM, but it is not well resistant to low aniline oil (like ASTM No. 3 oil) and polar solvents. AEM is typically chosen for applications requiring improved performance versus Nitrile rubber, Neoprene or reduced cost versus higher-end elastomers such as HNBR, FKM. It also usually is applied in automotive industry.

General Information

ASTM D 1418 Designation: AEM

ISO/DIN 1629 Designation: AEM

ASTM D2000 / SAE J 200 Codes: EE

Standard Color(s): Black

Hardness Range: 40 to 85 Shore A

Relative Cost: Medium- High

Cure system – Amine-Cured

Standard AEM compounds are Amine based vulcanization system.

Characteristics

- Excellent weather & ozone resistance

- Very good heat resistance

- Low compression set

- Resistant to most oils, greases (even with aggressive additives)

- Good low temperature properties

Service Temperatures

Standard Low Temperature: -30°C / -22°F

Standard High Temperature: 150°C / 300°F

Applications

Typical applications for AEM are all kind of static seals, hoses, gaskets in contact with oil as it happens in gear boxes, oil pumps, cam covers or others.

Vamac® is a registered trademark of DuPont Performance Polymers.

Polyurethane

POLYURETHANE (PU)

(Urethane – Polyurethane – Thermoplastic & Thermoset)

Polyurethane is a unique material that offers the elasticity of rubber combined with the toughness and durability of metal. Because urethane is available in a very broad hardness range (eraser-soft to bowling-ball-hard), it allows the engineer to replace rubber, plastic and metal with the ultimate in abrasion resistance and physical cost. Many applications using this ultra-tough material have cut down-time, maintenance time and cost of parts to a fraction of the previous figures.

Urethanes have better abrasion and tear resistance than rubbers, while offering higher load bearing capacity. Compared to plastics, Urethanes offer superior impact resistance, while offering excellent wear properties and elastic memory.

Urethanes have replaced metals in sleeve bearings, wear plates, sprockets, rollers and various other parts, with benefits such as weight reduction, noise abatement and wear improvements being realized.

Applications:

- Belts

- Metal forming pads

- Wear strips

- Bumpers

- Gears

- Bellows

- Machinery mounts

- Cutting Surfaces

- Sound-dampening pads

- Chute and hopper liners

- Prototype machined parts

- Gaskets

- Seals

- Rollers

- Roller covers

- Sandblast curtains

- Diaphragms