Delivering custom rubber extrusions in industry leading delivery times

Delivering custom rubber extrusions in industry leading delivery times

With decades of knowledge combined with our state-of-the-art equipment, if we can’t make your rubber extrusion design a reality; it is unlikely anyone can!

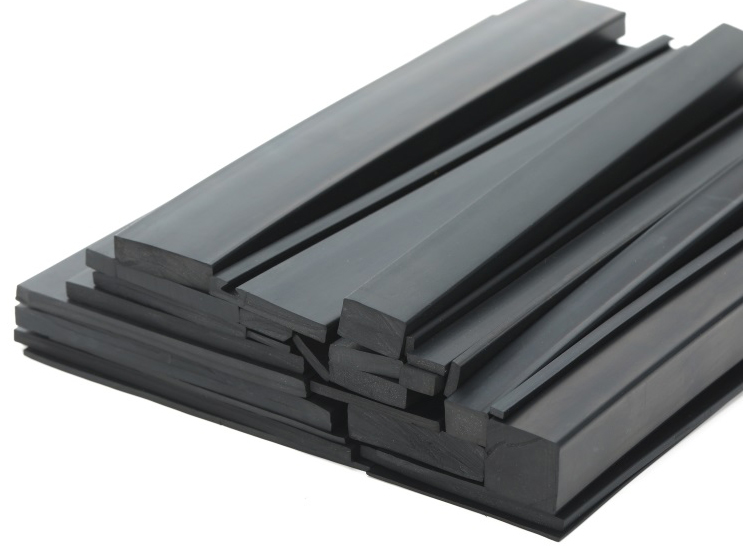

Rubber extrusions manufactured to meet your needs in days, not weeks. Offering some of the most competitive lead times in China, we have been championing the custom rubber extrusion process for many years.

We have over 1000 standard extrusion profiles, but should we not have what you’re looking for, we can manufacture the tooling required to produce your preferred design. Our extensive selection of machinery and equipment enables us to cut, drill and form your rubber extrusions with precision from as small as 5mm diameter all the way up to 300mm diameter.

At Hebei Shida Seal Group we have no minimum order on our stock and custom rubber extrusions, so whether you need 1m or 10,000m, we can fulfill your needs.

Rubber extrusion applications

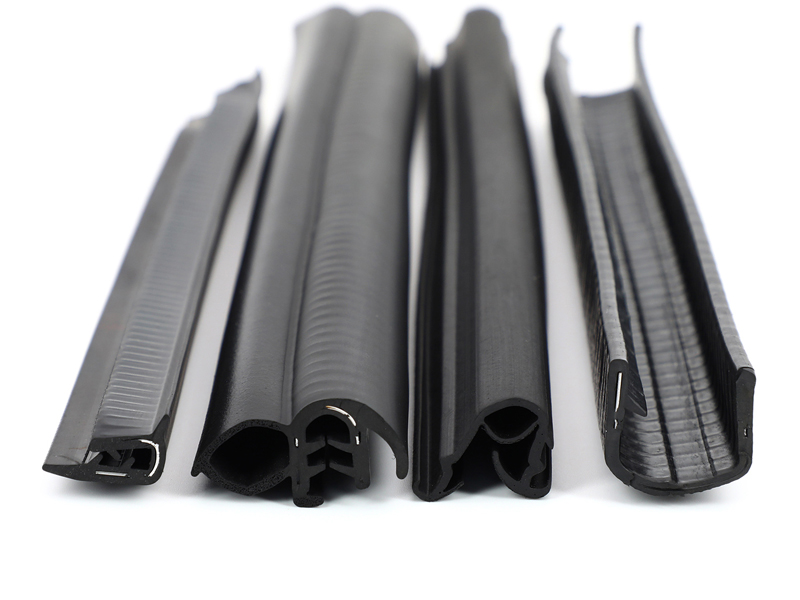

Custom rubber extrusions are versatile and can be applied to many projects. Our extrusions have a multitude of applications and profiles, some of the most common are:

- Rubber door seal

- Container door seal

- Rubber window seal

- Rubber P seal

- T section rubber seal

- U section rubber seal

- H section rubber seal

- Rubber edge trim

- D shaped rubber profile

- Rubber boat seals

About Us:

About Us:

Hebei Shida Seal Group is a leading manufacturer of Fire-Retardant Edge Trim, Flame-Retardant EPDM Rubber Trim, Bulb Trim Seals, Co-extruded Dual Durometer Sponge and Solid Rubber Extrusions, rubber strips, rubber seals, extrusions, rubber gaskets, extruded rubber parts and molded rubber parts from Qinghe, Hebei, China.

With combined experience within the industry, we have developed the talent, technical knowledge, engineering expertise and equipment to manufacture Special Profiles meeting the most stringent specifications. Our in-house tool and mould making as well as state-of-the-art development, manufacturing and testing methods ensure a maximum of product quality and reliability.

Capabilities:

- Certified to IATF (International Automotive Task Force) 16949

- Certified to ISO 14001 and ISO 45001 (Environment, Health and Safety)

- Production area 40,000 m²

- Processing of: EPDM Dense and Sponge, CR, NBR

- 5 continuous vulcanization (microwave + hot air ) extrusion lines

- 2 components extrudable

- 3 components extrudable

- Cutting and punching machines for precise lenghts

- Injection presses for mould corners

- Film vulcanization for corners and rings

Main Products:

- Custom EPDM Rubber Extrusions

- Automotive Weatherstripping, Door Seals, Window Seals

- Edge Trims & Seals,Self-Sealing Weatherstrips

- Window Channels, Flocking and Urethane Slip-coating

- Engineered TPV/TPE Profiles

- Co-extruded Trim Seals (dual durometers with a Metal Core, Segmented Steel or Wire Carrier)

Contact Us:

If your applications require Extruded Rubber Gaskets, and Seals, please feel free to contact us. We are committed to supplying our customers with robust rubber components and outstanding services.