What are Door Seal Extrusions?

Door seal extrusions are similar to molded rubber products, in that both are created by forcing heated rubber in a near-liquid state into a specially made mold or die under pressure. The extrusion process begins with an unvulcanized rubber compound being fed into an extruder. Revolving screws within the extruder carry the rubber toward the die; temperature and pressure increase as the material is forced through the opening. As it passes through the opening, the material generally swells to a certain extent, based on its chemical makeup and hardness. Plus/minus tolerances in the design of the extruded part’s cross section are often required to account for this swelling. Extruded products are often left unvulcanized prior to extrusion, which leaves the rubber in a softer, more pliable state post-extrusion. If this is the case, rubber extruded products generally need to be vulcanized before they can be used. Depending on the type of rubber being extruded, the vulcanization process will cause the material to either swell or shrink, both in its cross section and its length. In most cases, a length of rubber extrusion will experience greater dimensional reduction or expansion across the center than at its ends.

Extruded products are often left unvulcanized prior to extrusion, which leaves the rubber in a softer, more pliable state post-extrusion. If this is the case, rubber extruded products generally need to be vulcanized before they can be used. Depending on the type of rubber being extruded, the vulcanization process will cause the material to either swell or shrink, both in its cross section and its length. In most cases, a length of rubber extrusion will experience greater dimensional reduction or expansion across the center than at its ends.

Hebei Shida Seal Group produces door seals, rubber extrusions from EPDM, NBR. These compounds range from 50 to 80 durometer, filling a wide range of service needs. We also offer cut-to length services in addition to numerous packaging options.

Rubber Extrusions and Door Seals We Carry

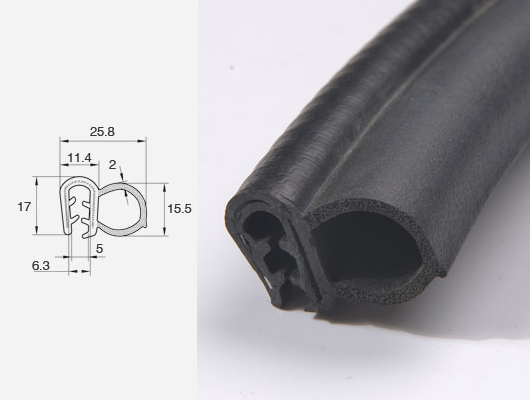

Our door seal extrusions, rubber extrusion and rubber seal inventory includes EPDM rubber seals, extruded rubber tubing and rubber cord stock, locking gaskets, rubber edge trim, weatherproof trim seals, U channel seals, angle section and edging rubbers, double D shape fenders, P seal rubber extrusions, solid rubber piping, rubber T section seal, rubber door seals, rubber window seals, water- and weather-resistant hollow rubber surface-mount seals, water- and weather-resistant foam rubber surface-mount seals, water- and weather-resistant hollow foam rubber surface-mount seals, high-temperature fire-rated hollow rubber surface-mount seals, push-on rubber seals, EPDM sponge rubber seals, silicone rubber seals, water- and weather-resistant flange-mount seals, extruded rubber shapes, seals and extruded rubber profiles, dual – durometer extrusions, etc.

Rubber Door Seals and Extrusions Capabilities

Rubber Door Seals and Extrusions Capabilities

Custom rubber extrusions are produced in a range of shapes and configurations ranging from tubes and pipes to custom rubber shapes with intricate designs. Though every project we work on is different, some products are more common than others, such as:

- Adhesive backed rubber seals

- Extruded rubber aircraft seals

- Automotive gaskets

- Chemical resistant rubber seals

- Extruded rubber cord

- Door seals

- High temperature rubber seals

- Low temperature seals

- Extruded rubber tubing

- Vibration absorption cushions

- and more

- EPDM Foam Strips

- Push-On Seals with Bulb on Top

- Push-On Seals with Bulb on Side

- Rubber Push-On Seals with Rubber Wiper

- High-Temperature Push-On Seals with Wiper

- Water- and Weather-Resistant Push-On T-Seals

Why Hebei Shida Seal Group?

Our facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision door rubber seal profiles in quantities from short run to full production runs. We have 5 extrusion lines, continuous cure microwave, precision cutting, and splicing machines, and also provide value-added finishing services. In addition, we offer in-house tool, die, and mold design and manufacturing to ensure that your parts are manufactured to the most exacting requirements.

Our facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision door rubber seal profiles in quantities from short run to full production runs. We have 5 extrusion lines, continuous cure microwave, precision cutting, and splicing machines, and also provide value-added finishing services. In addition, we offer in-house tool, die, and mold design and manufacturing to ensure that your parts are manufactured to the most exacting requirements.

We are committed to manufacturing your door seal extrusions to the highest standard of excellence so you can be assured that your component will meet or exceed your expectations.

Contact Us for Door Seals Rubber Extrusions

To meet customers’ exacting needs, our team of rubber experts strive to provide a cost competitive solution, within a short lead time from the design to production. If you want to contact us about any issue please call (+86)319 8032626 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.