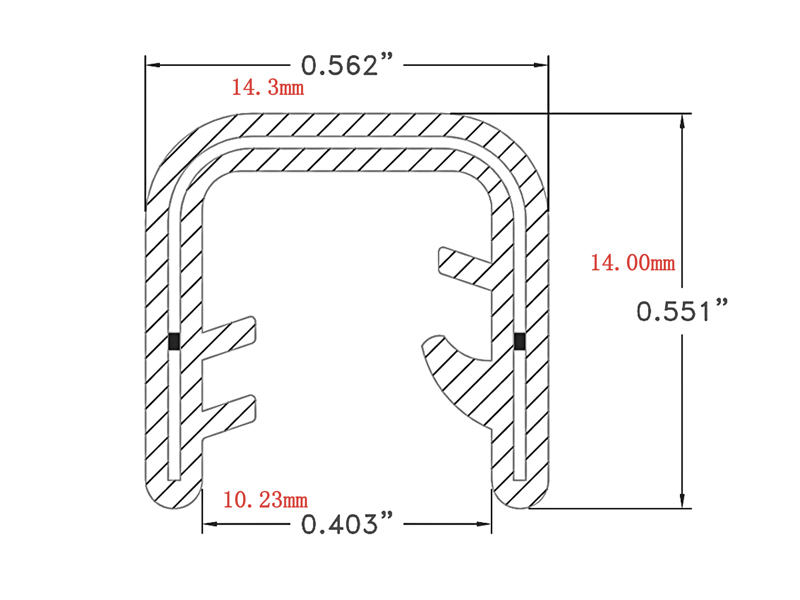

ES28-282-E80 PVC Edge Trim, Vinly Edge Trim, Rubber Edge Trims Manufacturers and Suppliers in China

Hebei Shida Seal Group is a leading manufacturer of PVC Edge Trim, Vinly Edge Trim, and Rubber Edge Trims for a wide range of industries. PVC Edge trim is used to protect personnel, vehicles, machinery, and equipment. Applications include vehicle doors, truck cabs, machine guards, and equipment cabinets. To help the rubber seal absorb impact, edge trim can contain either wire cores or segmented steel cores. Rubber edging is designed to be pushed into place over a flange.

PVC Edge Trims Features:

PVC Edge Trims Features:

- This edge trim seal contains interior tongues for additional gripping and a metal reinforcement for impact resistance. It also provides a finished appearance on the surfaces of vehicles, equipment, and machinery.

- This 80 durometer PVC edge trim seal has a medium density, or hardness, on the Shore A scale. It is harder than a pencil eraser but softer than a hockey puck for the right balance between compressibility and impact resistance.

- Polyvinyl chloride (PVC) resists weathering, chemicals, and abrasion. It is strong, lightweight, mechanically tough, and cost-effective.

- ES28-282-E80 is used in various heavy equipment and transportation applications. Use this edge trim for a hatch seal on a boat, a window seal for a truck, a door seal for a car, or a compartment seal for an RV or truck toolbox.

- Press the edge trim over the edge or flange by hand or use a hand tool such as a rubber mallet. The gripping tongues help to attach the seal to the edge or flange and hold it in place without the use of fasteners.

PVC Edge Trims Application:

PVC Edge Trims Application:

- Construction And Agricultural Equipment: farm tractors, combines, harvesters, tree shakers, planters, balers, chaser bins, excavators, bulldozers, backhoes, dragline excavators, graders, wheel tractor scrapers, trenchers, loaders, tower cranes, pavers, compactors, telehandlers, feller bunchers, dump trucks, pile boring or pile driving machines, road patching machines

- On Road And Offroad Vehicles: Cars, trucks, boats, and RVs; campers and outdoor equipment, EV cars, EV trucks, and EV buses (plug-in, hybrid, and fuel cell designs), flatbed dump trucks, work trucks, and crane trucks

- Marine Applications: boats, yachts, passenger vessels, pleasure craft, cargo ships and carriers Applicable Uses: DOOR SEALS: for exposed metal or plastic edges

- Boat Hatch Seals: for the hatches on boats, including ocean-going watercraft

- Enclosure Seals: for metal or plastic enclosures

- Truck Toolbox Seals: for the seals on toolboxes used in work trucks Tips for use: Edge trim needs to have the same thickness as the edge. The length of the legs need to cover the flange. Shallower flanges require shorter leg lengths and longer flanges need longer legs.

Edge Trims Materials

- Edge trim materials include EPDM, a synthetic rubber that resists moisture and withstands temperature extremes. This closed-cell rubber also provides a relatively high degree of electrical insulation. Unlike some other elastomers, EPDM edge trim exhibits superior UV resistance. This makes EPDM edge trim a good choice for mobile equipment and other outdoor applications.

- PVC edge trim is often used with interior applications such as storage cabinets. A lightweight plastic with a closed-cell structure, PVC edge trim withstands the absorption of water and will not swell like wood. PVC cracks at cold temperatures, however, and may become discolored from prolonged exposure to sunlight.

- Edge trim can be reinforced with wire cores or segmented wire cores. Solid steel cores withstand impact under cold temperature and cold weather conditions. Edge trim with segmented steel cores may contain cold-rolled steel that provides good elongation properties.

We always manufacture our Extruded PVC Edge Trims from the highest quality compounds available. This ensures that our PVC Edge Trims are not only suitable for use, but also made to last. Despite offering high strength and tear resistance, our window seals are also highly flexible. This enables our profiles to fit around a wide variety of curves.

Our facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision PVC Edge Trim in quantities from short run to full production runs. We have 5 extrusion lines, continuous cure microwave, precision cutting, and splicing machines, and also provide value-added finishing services. In addition, we offer in-house tool, and mold design and manufacturing to ensure that your parts are manufactured to the most exacting requirements.

Hebei Shida Seal Group is uniquely qualified to manufacture custom PVC Edge Trims for your application. Our quality management system is IATF 16949:2016 accredited. We can provide PPAP Level 3 documents for OEM clients.

If you want to contact us about any issue please call (+86)319 8032626 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.