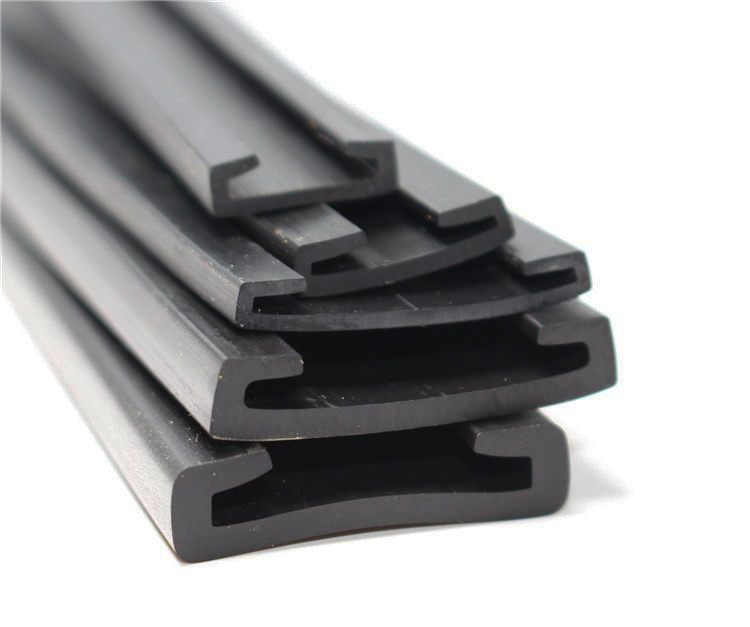

Hebei Shida Seal Group is a China manufacturer of high-quality nitrile rubber (NBR) extrusions of many forms from simple cylindrical cord to complex, multi-cavity contoured parts, all designed to perfectly seal against air, fluid gas and to be aesthetically pleasing where they are used as visible parts such as edge trims or buffers.

All our nitrile extrusions are made to order, produced using dimensions, samples or drawings provided by customers, from which a tool is made and a sample produced for approval, ensuring the final product perfectly fits the application. Nitrile rubber extrusions are preferred in automotive applications such as the production of hoses, seals and fuel tank seals.

All our nitrile extrusions are made to order, produced using dimensions, samples or drawings provided by customers, from which a tool is made and a sample produced for approval, ensuring the final product perfectly fits the application. Nitrile rubber extrusions are preferred in automotive applications such as the production of hoses, seals and fuel tank seals.

Why use Nitrile Rubber Extrusion?

Nitrile rubber extrusions can take many forms and profiles, all looking very different in appearance, but as they are produced using the exact same material, they will still all possess the same mechanical properties making it a popular choice across many industries.

Nitrile rubber extrusions are an excellent product for creating an air, dust and watertight seal, with good tensile strength, anti-abrasion properties and resistance to petrol, mineral & vegetable oils and some acids and alkalis.

The material has a working temperature range of -20°C to +70℃. Nitrile rubber extrusions are a popular choice for automotive belting, hoses, o-rings, and oil seals within hydraulics and flanges.

Benefits of Nitrile Rubber Extrusion

Benefits of Nitrile Rubber Extrusion

- Water, mineral/oil, petrol resistance.

- Can be formed into complex seals and extrusions

- Abrasive resistant

- Water Proof

- Excellent sea against gasses

- Excellent for automotive applications

Advantages of Using Nitrile Rubber Extrusion

There are many advantages to using Nitrile rubber extrusions, mainly its properties which include high tensile strength, good elongation, high resistance oils, fuels, grease, many acids and water, excellent compression set and is abrasion-resistant. Nitrile rubber extrusions have excellent resistance to hot oil, which makes it a popular material for use within the automotive industry where it can be found in the form of oil-seals, engine hoses and o-rings, to name just a few parts.

The process of nitrile rubber extrusions create identical cross-sectional shapes products in varying lengths as required by the customer from short, pre-cut sections, right through to rolls of extruded product 100’s of meters long. As nitrile rubber profiles are manufactured using raw material, we have the ability to design and offer bespoke and unique profiles to perfectly match our customer’s specifications.

Our facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision extruded nitrile rubber profiles in quantities from short run to full production runs. We have 5 extrusion lines, continuous cure microwave, precision cutting, and splicing machines, and also provide value-added finishing services. In addition, we offer in-house tool, and mold design and manufacturing to ensure that your parts are manufactured to the most exacting requirements.

Hebei Shida Seal Group is uniquely qualified to manufacture custom nitrile rubber seals for your application. Our quality management system is IATF 16949:2016 accredited. We can provide PPAP Level 3 documents for OEM clients.

If you want to contact us about any issue please call (+86)319 8032626 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.