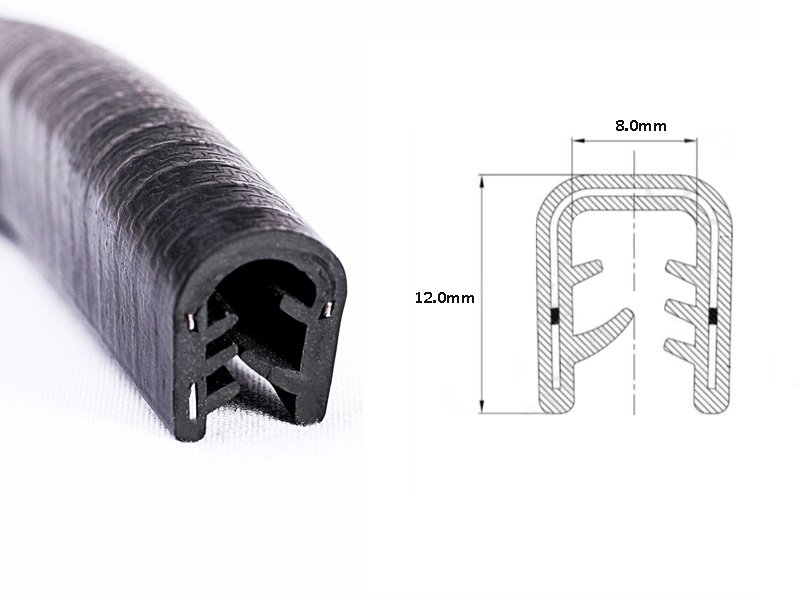

Description

Rubber Edge Trim is a flexible rubber material used to create an edge around the perimeter of an object. It protects edges from wear and tear, provides a decorative finish, & reduces the risk of injury from sharp edges.

Feature

- Weather-resistant

- Made from EPDM dense rubber

- Good tear and abrasion resistance

- Help prevent dirt and moisture from entering

- Wide operating temperature range

Materials

NBR – Nitrile or NBR cords are suitable for contact with lubricants, oils, hydraulic fluids, etc. They can be used in temperatures ranging from -30°C up to +120°C (-20°F up to 250°F). These cords are also known for their breaking strength. They are resistant to abrasion and deformation.

EPDM – EPDM cords are suitable for outdoor use. They are resistant to UV rays, Weather conditions, Hydraulic & brake fluids, Moisture and Ozone. The operating temperature typically ranges from -40°C up to 120°C.

Silicone – Silicone cords are recognized for their Thermal stability, Low toxicity, Resistance to fungi and bacteria development, Flexibility, Electrical insulation characteristics and Resistance to ozone, UV radiation, oxygen, etc. These cords are commonly found in the pharmaceutical, medical, and food industries. Their operating temperature ranges from -60°C up to 280°C(-75°F up to 540°F).

Rubber Edge Trim Applications

Rubber Edge Trim Applications

Automotive – Rubber edge trim is often used in the automotive industry to provide a secure seal between two parts, such as two panels or a panel & a window. This helps reduce vibration & noise, while also providing an aesthetic finish.

Appliances – Rubber edge trim is a great way to seal the edges of appliances such as refrigerators, freezers, & dishwashers. It provides a secure seal to prevent moisture & dust from entering the appliance, while also adding a decorative touch.

Marine – In the marine industry, rubber edge provides a secure seal and helps to keep out water, dust, and other debris.

Furniture – Rubber edge trim provides a secure seal between two pieces of furniture. This helps to protect the furniture & keep out dust and debris.

Industrial – In the industrial sector, rubber edges deliver a secure, reduced vibration and noise.

About Us

Hebei Shida Seal Group is a manufacturer of high-quality rubber edge trims. We offer these trims in coil forms, cut pieces, or straight lengths. With combined experience within the industry, we have developed the talent, technical knowledge, engineering expertise and equipment to manufacture rubber edge trims meeting the most stringent specifications. Our in-house tool and mould making as well as state-of-the-art development, manufacturing and testing methods ensure a maximum of product quality and reliability.

Capabilities:

- Certified to IATF (International Automotive Task Force) 16949,

- Certified to ISO 14001 and ISO 45001 (Environment, Health and Safety)

- Production area 40,000 m²

- Processing of: EPDM Dense and Sponge, CR, NBR

- 5 continuous vulcanization (microwave + hot air ) extrusion lines

- 2 components extrudable

- 3 components extrudable

- Cutting and punching machines for precise lenghts

- Injection presses for mould corners

- Film vulcanization for corners and rings

Main Products:

- Custom Rubber Extrusions and Profiles

- Automotive Weatherstripping, Door Seals, Window Seals

- Edge Trims & Seals,Self-Sealing Weatherstrips

- Window Channels, Flocking and Urethane Slip-coating

- Engineered TPV/TPE Profiles

- Co-extruded Trim Seals (dual durometers with a Metal Core, Segmented Steel or Wire Carrier)

Contact Us:

If your applications require custom rubber edge trims, please feel free to contact us. We are committed to supplying our customers with robust rubber components and outstanding services.