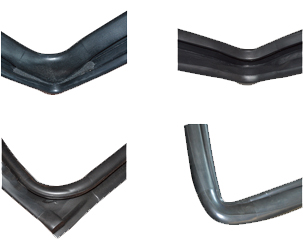

Hebei Shida Seal Group offers custom rubber molded corners to meet any customer’s specifications. Rubber Molded Corners can be fabricated into a variety of configurations through molding, hot splicing, or cold bonding.

Hebei Shida Seal Group offers custom rubber molded corners to meet any customer’s specifications. Rubber Molded Corners can be fabricated into a variety of configurations through molding, hot splicing, or cold bonding. Rubber Molded Corners yield the ultimate corner. Rubber is injected under high pressure to bond the two pieces into a complete corner.

Hot splicing uses a similar method to molding. However, hot splicing bonds the corner extrusions by “buttering” the ends with a liquid rubber adhesive and heat curing the parts into a complete corner.

Cold splicing seals the two end by applying an air cured adhesive to create a complete corner.

Typical applications are windshield weatherstrips, glass run channels for vehicles.