Hebei Shida Seal Group is a leading manufacturer of high quality rubber extrusions products from Qinghe, Hebei, China. We maintain an extensive inventory of extruded rubber seal products in a wide range of variety, shape, and sizes that can meet the diverse needs of most applications.

Rubber extrusions, such as large gaskets, are often joined at the ends to produce a ring or circle. With this splicing technique, we place the two ends (slightly apart from each other) of the finished extrusion in a small injection molding press, close the die, and inject the uncured rubber into the die cavity that is already at the curing temperature of the rubber. The curing rubber bonds to the ends of the extrusion, creating a circle and forming the gasket.

Vulcanization is a process which uses heat, rubber adhesive, pressure and time to chemically bond the two ends together. There are a variety of joints which can be bonded. Round cord or irregular profiles may be vulcanized to endless gaskets. Applications such as window frame gaskets, door gaskets, filter housing gaskets and lid gaskets. The uses are as unlimited as your imagination will allow.

- The Butt Splice is used for fabricating endless gaskets where there will be limited or no strain on the splice.

- The Bevel Splice is an alternate to the butt splice and is used where the cross sectional area is insufficient to form a suitable bond by using the butt splice.

- The Step Splice provides maximum bond strength permitting nominal deformation under compression or tension when used as a static seal.

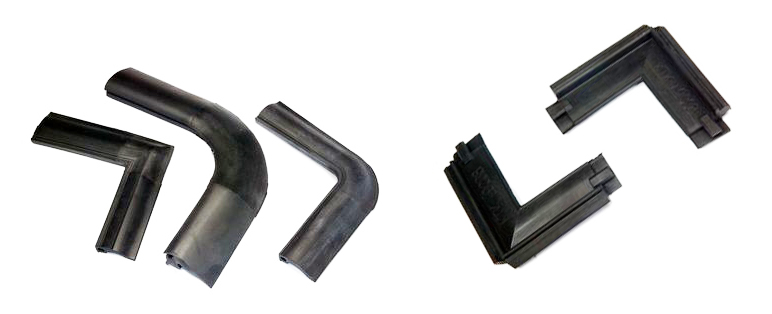

- The Corner Splice is used to form gaskets of special configurations. Spliced corners provide a satisfactory static seal where the splice is not under strain. Full Molded Corners with step splices away from the corner are recommended where the gasket will be under strain.

- Molded Splices – Many gaskets and ring seals may be produced economically by splicing extruded shapes to form complete gaskets.

We often refine this process to create square corners and other ‘molded features’ that combine to make an extrusion useful in the application for which it is designed. Less sophisticated ‘cold splicing’ or ‘bonding’ techniques can also be employed to affect the same solution. These alternatives usually sacrifice esthetics and strength for lower tooling costs.

Hebei Shida Seal Group’s extensive splicing capabilities allow us to produce rubber seals and gaskets for a broad array of automotive, chemical processing, construction, food processing, industrial, oil and gas, as well as wire and cable applications.

We are uniquely qualified to manufacture custom spliced door seals, gaskets, vulcanized spliced and rubber extrusions for your application.

If you want to contact us about any issue please call (+86)319 8032626 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.