Description:

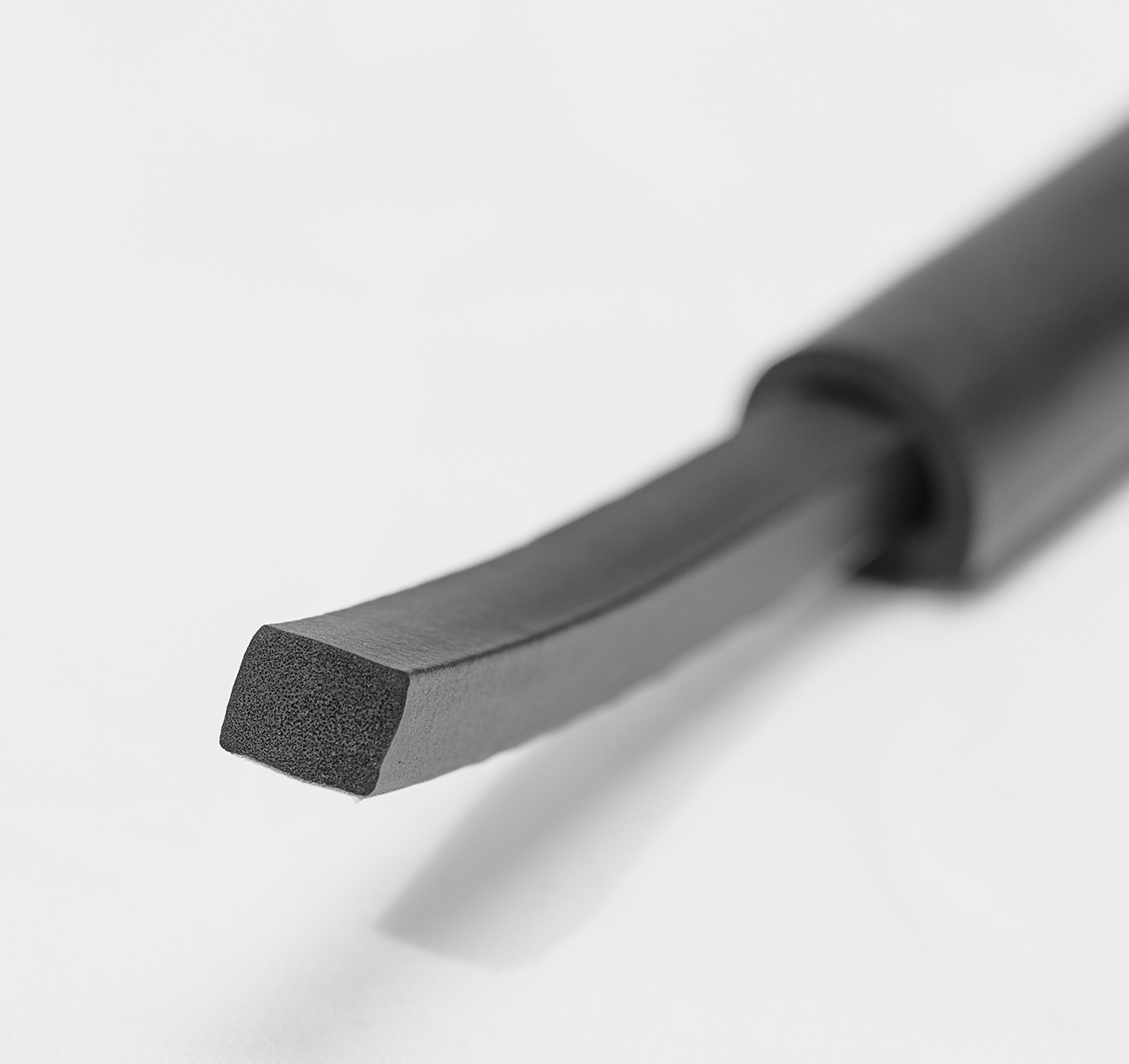

Sponge Rubber Extrusions, Rubber Sponge Extrusion, EPDM Rubber Seals

Hebei Shida Seal Group can custom extrude rubber sponge for various industries from a wide variety of compounds, grades and specifications. We can help you through the entire extrusion process – from choosing the right material to using the most cost-effective manufacturing methods.

Sponge rubber extrusion is used in a broad range of applications. They can be an economical option as a seal, used to eliminate noise, and used to eliminate vibrations. EPDM is often a good choice for an outdoors seal and is one of the most common choices. There are other material options, including combinations of materials.

Sponge Rubber Extrusions Profiles

- “D” Shaped Profiles

- “L” Shaped Profiles

- “P” Shaped Profiles

- “T” Shaped Profiles

- “U” Channel

- Round Cord

- Squares and Rectangles

- Other profiles are available, let us know your requirements

Sponge Rubber Extrusions Applications

- Windowpanes

- Garage Doors

- Enclosed Cargo Trailers

- Windshields

- Sunroofs

- Tonneau Covers

- Boat Hatches

- RV

- ATV and other off-road vehicles

- Appliances

- Ag and Construction

- Electronic Enclosures

- Other

Sponge Rubber Extrusions Features

- EPDM is water resistant and can stand up to harsh weather conditions such as sleet and snow.

- EPDM has excellent resistance to abrasions and tears and ability to stand up to the degrading effects of weathering, ozone and UV ray exposure.

- EPDM also offers good electrical resistance. Its chemical properties make it especially suitable for electrical insulation and gaskets.

- EPDM resists polar solvents, and not just water, but also acids, alkalies, and phosphate esters.

- EDPM does a great job of withstanding steam and low and high temperatures

- EPDM has a low compression set, so it won’t lose much resilience over prolonged pressure.

We can supply custom sponge rubber extrusions with or without pressure-sensitive adhesive (PSA) backing. Rubber sponge extrusion cross-sectional tolerances are compliant with rubber industry-standard RMA Precision tolerances.

We are uniquely qualified to manufacture custom EPDM sponge rubber extrusion for your application. Our quality management system is IATF 16949:2016 accredited. We can provide PPAP Level 3 documents for OEM clients.

About Us

Hebei Shida Seal Group is a leading manufacturer of sponge rubber extrusions with or without pressure-sensitive adhesive (PSA) backing, Vertical Bulb Trim Seals, Co-extruded Dual Durometer Sponge and Solid Rubber Extrusions with Flexible Wire Core 75001360, rubber strips, rubber seals, extrusions, rubber gaskets, extruded rubber parts and molded rubber parts from Qinghe, Hebei, China.

With combined experience within the industry, we have developed the talent, technical knowledge, engineering expertise and equipment to manufacture Special Profiles meeting the most stringent specifications. Our in-house tool and mould making as well as state-of-the-art development, manufacturing and testing methods ensure a maximum of product quality and reliability.

Capabilities:

- Certified to IATF (international Automotive Task Force) 16949,

- Certified to ISO 14001 and ISO 45001 (Environment, Health and Safety)

- Production area 40,000 m²

- Processing of: EPDM Dense and Sponge, CR, NBR

- 5 continuous vulcanization (microwave + hot air ) extrusion lines

- 2 components extrudable

- 3 components extrudable

- Cutting and punching machines for precise lenghts

- Injection presses for mould corners

- Film vulcanization for corners and rings

Main Products:

- Custom EPDM Rubber Extrusions

- Automotive Weatherstripping, Door Seals, Window Seals

- Edge Trims & Seals,Self-Sealing Weatherstrips

- Window Channels, Flocking and Urethane Slip-coating

- Engineered TPV/TPE Profiles

- Co-extruded Trim Seals (dual durometers with a Metal Core, Segmented Steel or Wire Carrier)

Contact Us:

If your applications require ponge rubber extrusions with or without pressure-sensitive adhesive (PSA) backing, Vertical Bulb Trim Seals, Co-extruded Dual Durometer Sponge and Solid Rubber Extrusions, EPDM Trim Seals, Rubber Profiles, Extruded Rubber Gaskets, and Seals, please feel free to contact us. We are committed to supplying our customers with robust rubber components and outstanding services.